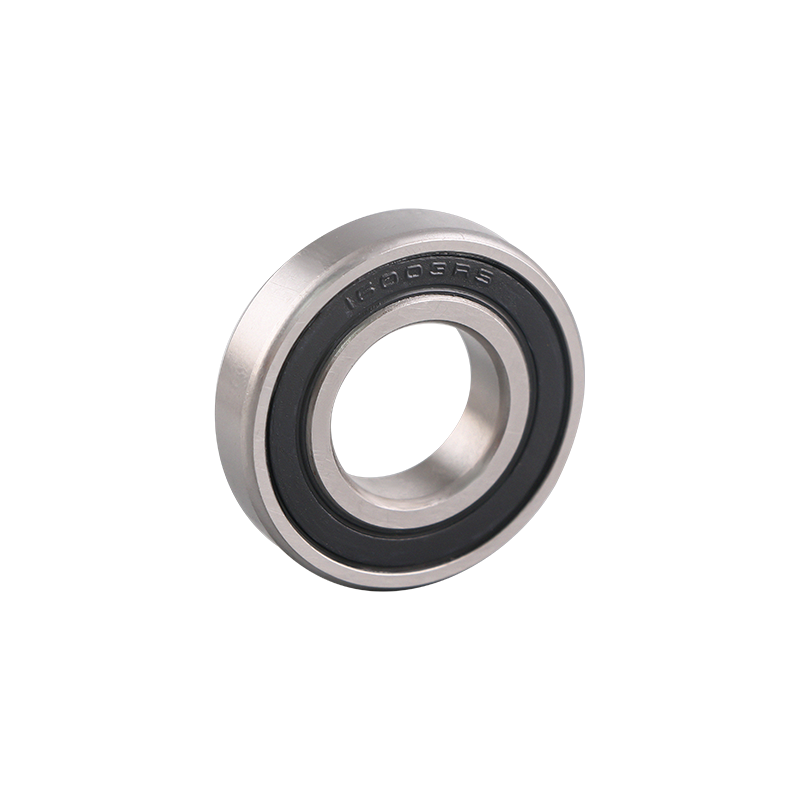

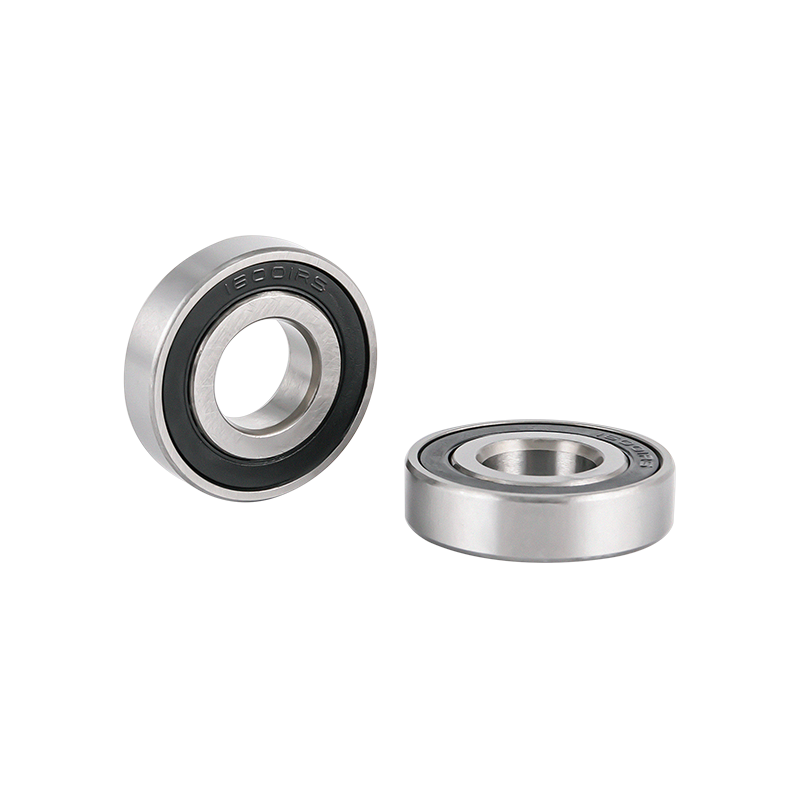

What is Deep Groove Ball Bearing

A

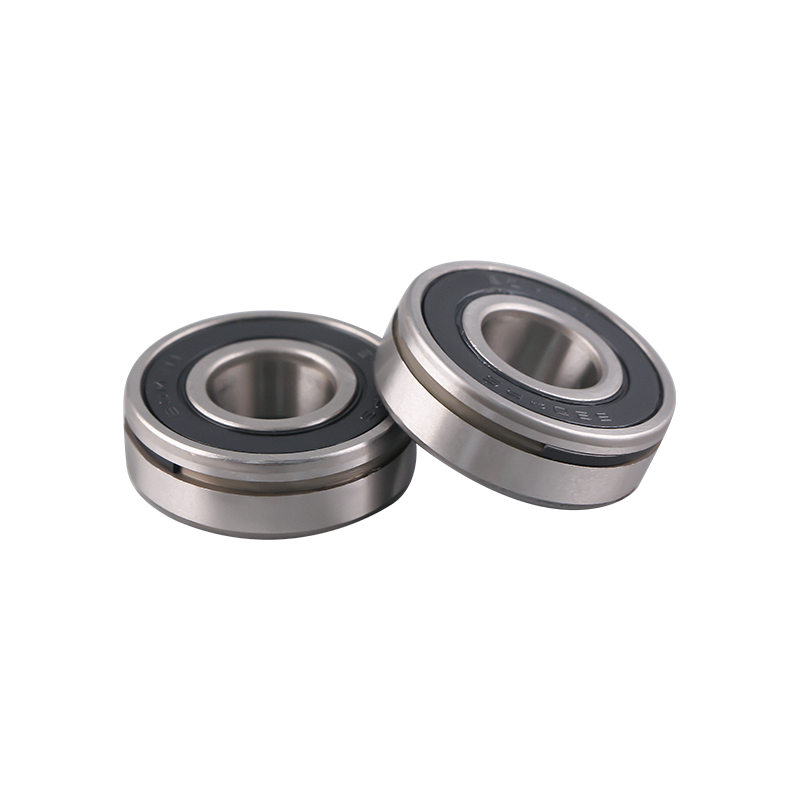

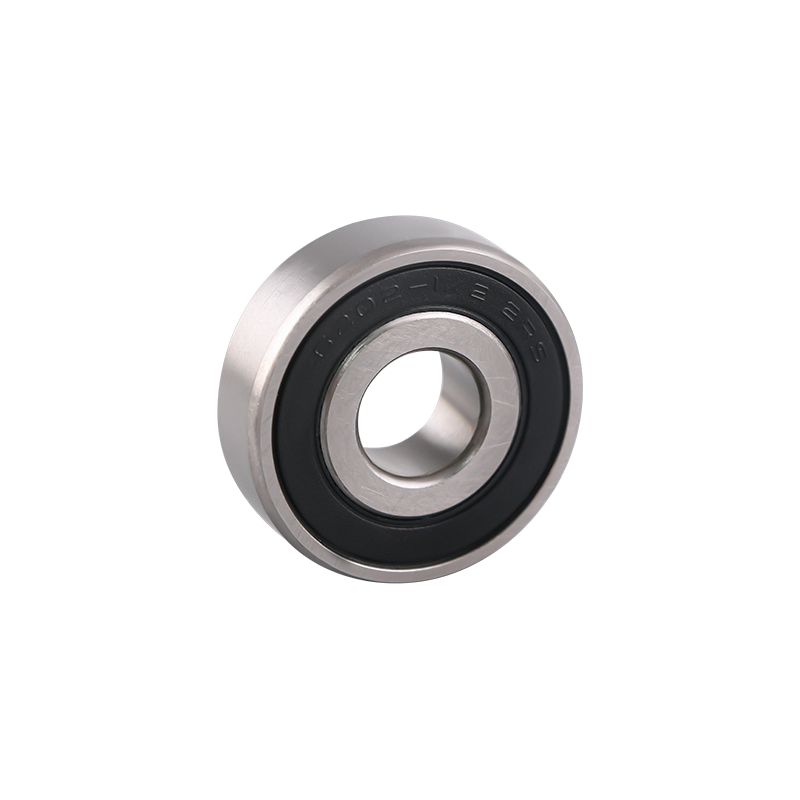

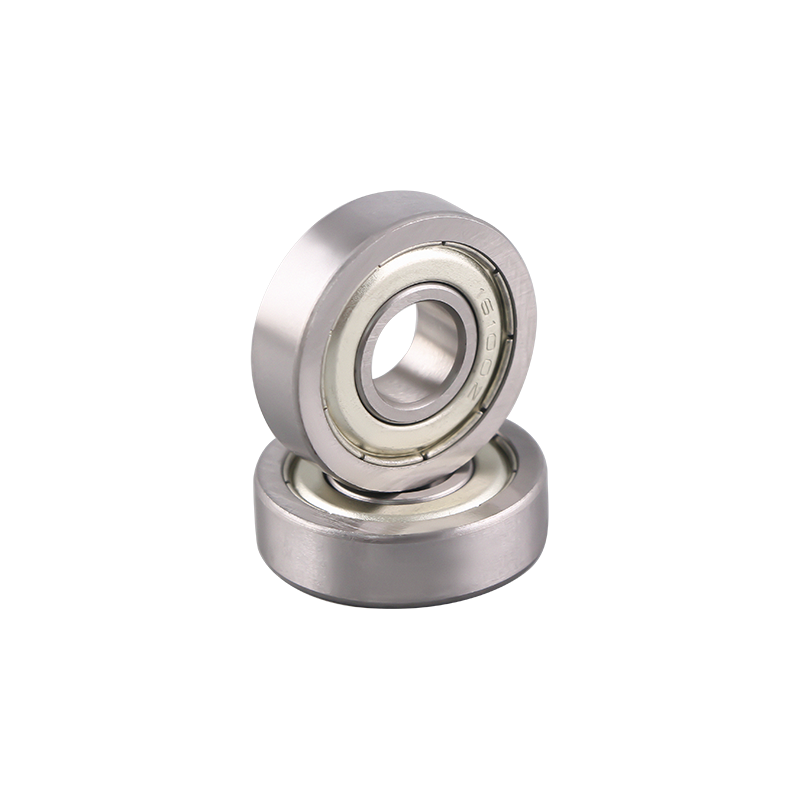

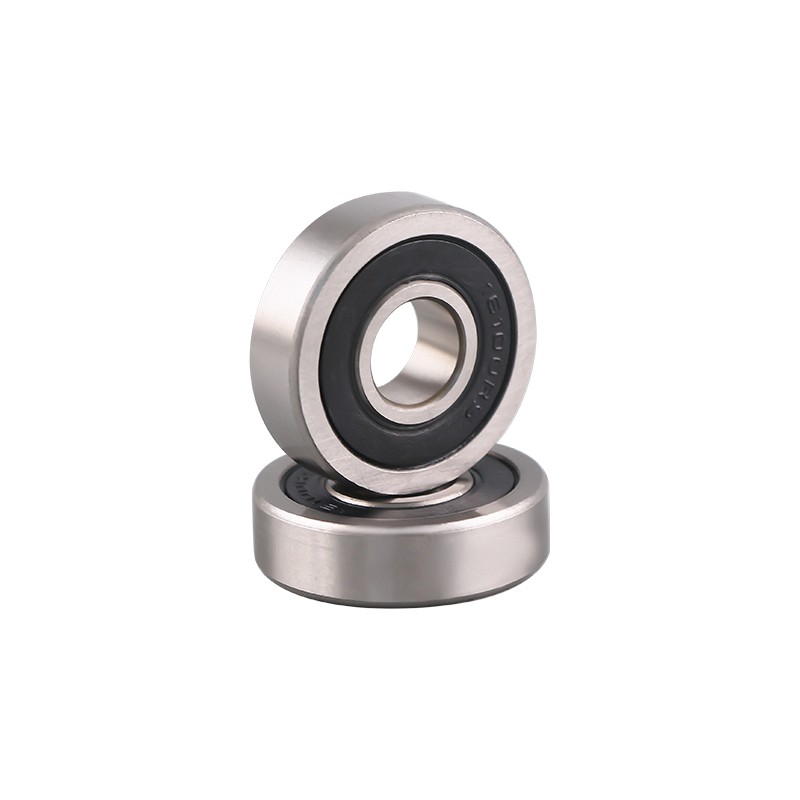

deep groove ball bearing is a type of rolling-element bearing commonly used in industrial and mechanical applications to support axial and radial loads. It consists of an inner and outer ring, a set of steel balls and a cage to keep the balls separated.

The inner and outer rings of a deep groove ball bearing have deep grooves, which allow the balls to rotate freely within the bearing. This design distributes the load evenly over a larger area, reducing friction and increasing the bearing's lifespan.

Deep groove ball bearings are available in a variety of sizes, load capacities, and materials, such as stainless steel or ceramic. They are used in many applications, including electric motors, pumps, gearboxes, and automotive components, and are known for their reliability, durability, and low maintenance requirements.

How to use Deep Groove Ball Bearing

Deep groove ball bearings are commonly used in a variety of applications, including motors, generators, pumps, and machine tools. Here are some general steps on how to use a deep groove ball bearing:

Proper Handling: Before using a deep groove ball bearing, it is important to handle it with care to avoid any damage to the bearing's surfaces. Make sure to keep the bearing in its original packaging until ready to use, and avoid dropping or striking the bearing during handling.

Proper Installation: Proper installation of the bearing is critical to ensure its performance and longevity. It is important to clean the bearing seat and shaft before installation, and to use the correct tools and equipment to properly mount the bearing in its seat.

Lubrication: Deep groove ball bearings require proper lubrication to function correctly. Be sure to use the correct type and amount of lubricant recommended by the bearing manufacturer.

Monitoring: After installation, monitor the performance of the bearing to ensure it is operating correctly. Pay attention to any unusual noises or vibrations, which may indicate a problem with the bearing.

Maintenance: To ensure the longevity of the bearing, it is important to follow the manufacturer's recommended maintenance schedule. This may include regular lubrication, cleaning, and inspection.

Overall, the proper use and maintenance of a deep groove ball bearing can help ensure its performance and longevity in your application. It's always recommended to consult the manufacturer's guidelines for specific instructions on handling, installation, lubrication, and maintenance of your particular bearing.