Ball bearings are a critical component in various industries, playing a vital role in enabling smooth and efficient motion. They are widely used in machinery, automotive applications, aerospace systems, and many other fields where rotational movement is required. Ball bearings offer low friction, high precision, and durability, making them indispensable in countless applications.

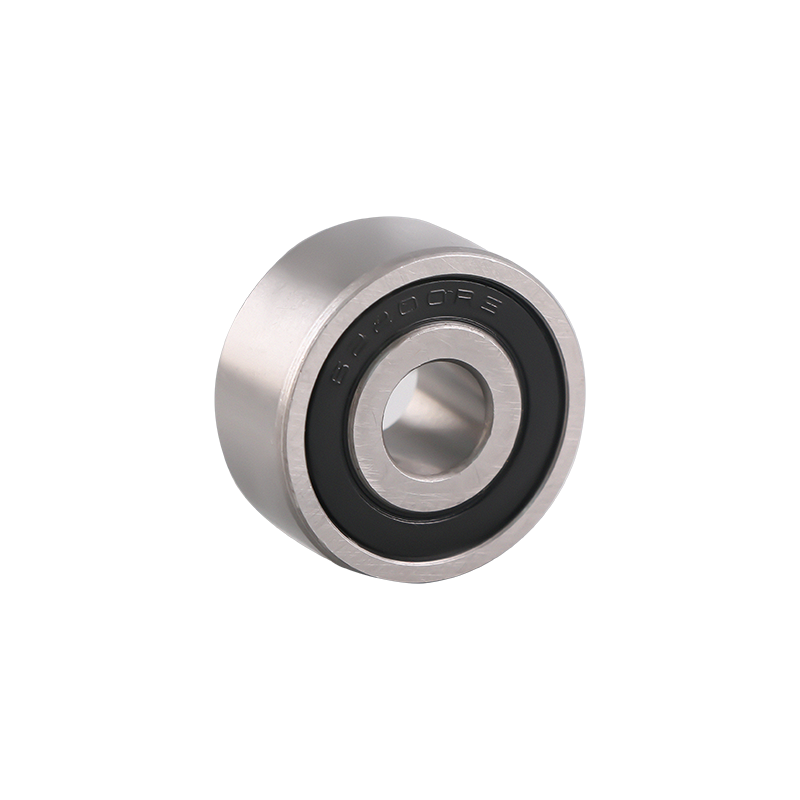

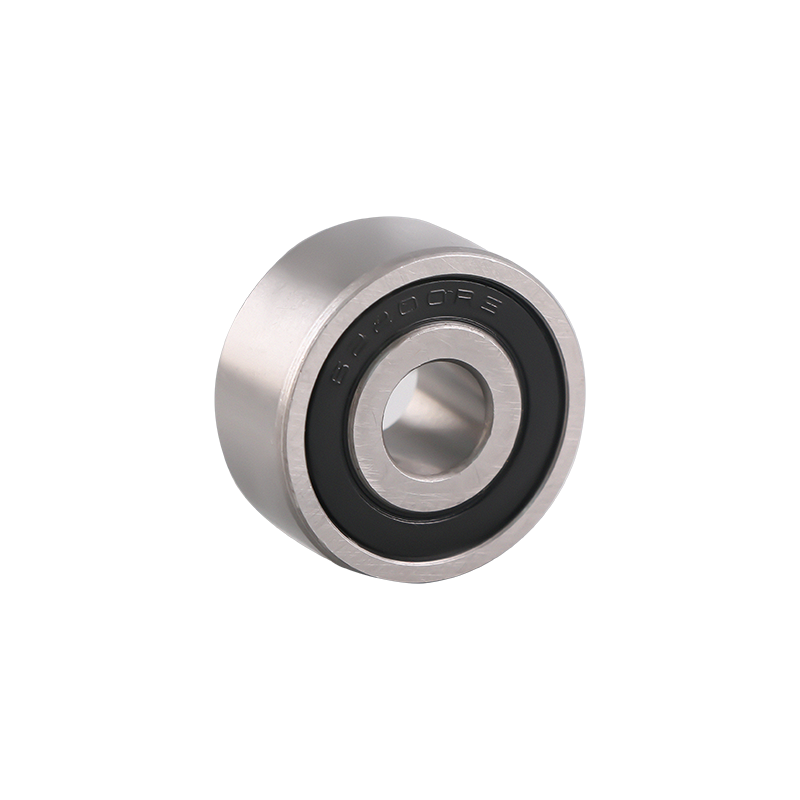

A ball bearing is a type of rolling element bearing that uses balls to reduce friction between moving parts. It consists of an inner and outer ring, a cage to hold the balls in place, and the balls themselves. When subjected to radial or axial loads, the balls roll between the inner and outer rings, minimizing the contact area and reducing frictional resistance. This design allows for efficient motion transfer, enhancing the overall performance of the machinery.

The key advantage of ball bearings is their ability to handle both radial and axial loads simultaneously. Radial loads act perpendicular to the shaft's axis, while axial loads act parallel to the shaft's axis. By distributing these forces across multiple balls, ball bearings can handle higher loads than other bearing types, such as plain bearings. This characteristic makes ball bearings highly desirable in applications that require both radial and axial support.

Ball bearings come in a variety of types, each designed to meet specific requirements based on load capacity, speed, and environmental conditions. Some common types include deep groove ball bearings, angular contact ball bearings, thrust ball bearings, and self-aligning ball bearings.

Deep groove ball bearings are the most widely used type and can accommodate both radial and axial loads. They have a deep groove running along the inner and outer rings, enabling them to handle high-speed and high-temperature applications effectively. Angular contact ball bearings, on the other hand, are designed to support high axial loads in a single direction. They have a contact angle between the balls and the raceways, allowing them to transmit thrust loads efficiently.

Thrust ball bearings are primarily used to support axial loads and consist of two washers with raceways and a set of balls sandwiched between them. These bearings are suitable for applications where high axial loads are present, such as automotive transmissions and machine tools. Self-aligning ball bearings have the unique ability to compensate for shaft misalignment. They have two rows of balls, which enables them to handle both radial and moderate axial loads while accommodating shaft deflection or misalignment.