Deep groove ball bearings and angular contact ball bearings are representative rolling bearings. They are widely used and can withstand radial loads and bidirectional axial loads. They are suitable for high-speed rotation and occasions requiring low noise and low vibration. Or the sealed bearing with rubber sealing ring is pre-filled with grease, and the outer ring has a snap ring or a flange bearing, which is not only easy to locate in the axial direction, but also easy to install in the housing. The size of the maximum load bearing is the same as that of the standard bearing. , but there is another filling groove in the inner and outer rings, which increases the number of balls and increases the rated load.

Different types and load directions:

Deep groove ball bearings are the most common type of rolling bearings. It mainly bears radial load, and can also bear radial load and axial load at the same time. When it is only subjected to radial load, the contact angle is zero. When the deep groove ball bearing has a large radial clearance, it has the performance of an angular contact bearing and can bear a large axial load. The friction coefficient of the deep groove ball bearing is very small, and the limit speed is also high.

Angular contact ball bearings:

There is a contact angle between the ferrule and the ball. The standard contact angle is 15/25 and 40 degrees. The larger the contact angle, the greater the axial load capacity. The smaller the contact angle, the more conducive to high-speed rotation. Radial load and unidirectional axial load, DB combination, DF combination and double row angular contact ball bearings can bear radial load and bidirectional axial load, DT combination is suitable for large unidirectional axial load and rated load of a single bearing In the case of insufficient, high-speed ACH type bearings, with small ball diameter and large number of balls, are mostly used for machine tool spindles. In general, angular contact ball bearings are suitable for high-speed, high-precision rotation applications.

Structural differences:

Deep groove ball bearings and angular contact ball bearings with the same inner and outer diameters and widths have the same inner ring size and structure, while the outer ring size and structure are different:

1. Deep groove ball bearings have double shoulders on both sides of the outer ring channel, while angular contact ball bearings are generally single shoulders;

2. The curvature of the outer ring of the deep groove ball bearing is different from that of the angular contact ball, the latter is often larger than the former;

3. The position of the outer ring of the deep groove ball bearing is different from that of the angular contact ball bearing, and the non-central position, the specific value of which is to be considered in the design of the angular contact ball bearing, and is related to the degree of the contact angle;

In terms of use:

1. The uses of the two are different. Deep groove ball bearings are suitable for bearing radial force, small axial force, combined axial radial load and moment load, while angular contact ball bearings can withstand a single radial load and a larger axial load. The axial load (varies with the contact angle), and the duplex pairing (varies with the pairing method) can bear the bidirectional axial load and moment load.

2. The limit speed is different. The limit speed of angular contact ball bearings of the same size is higher than that of deep groove ball bearings.

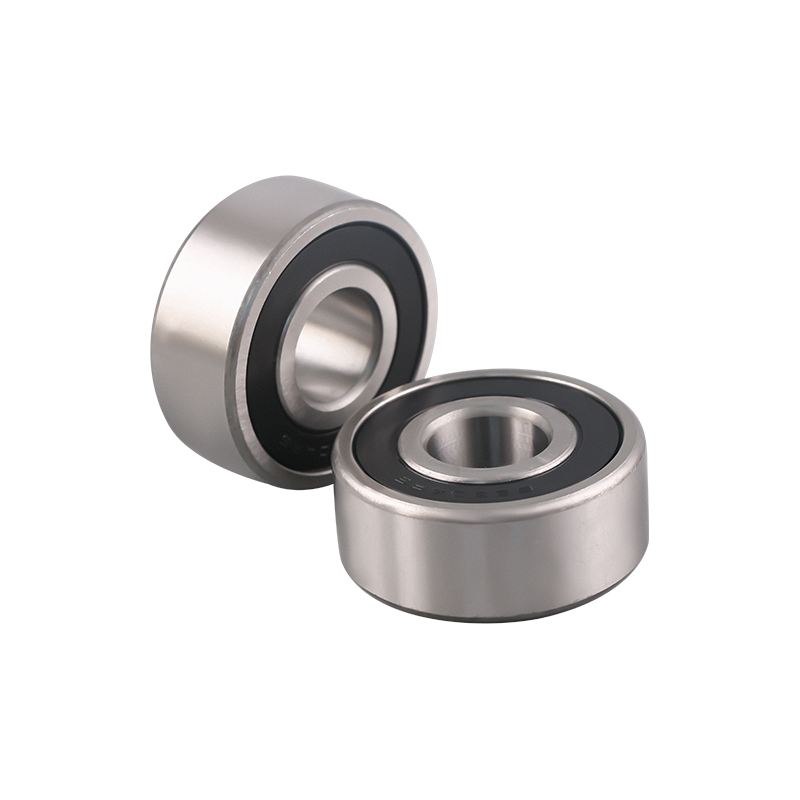

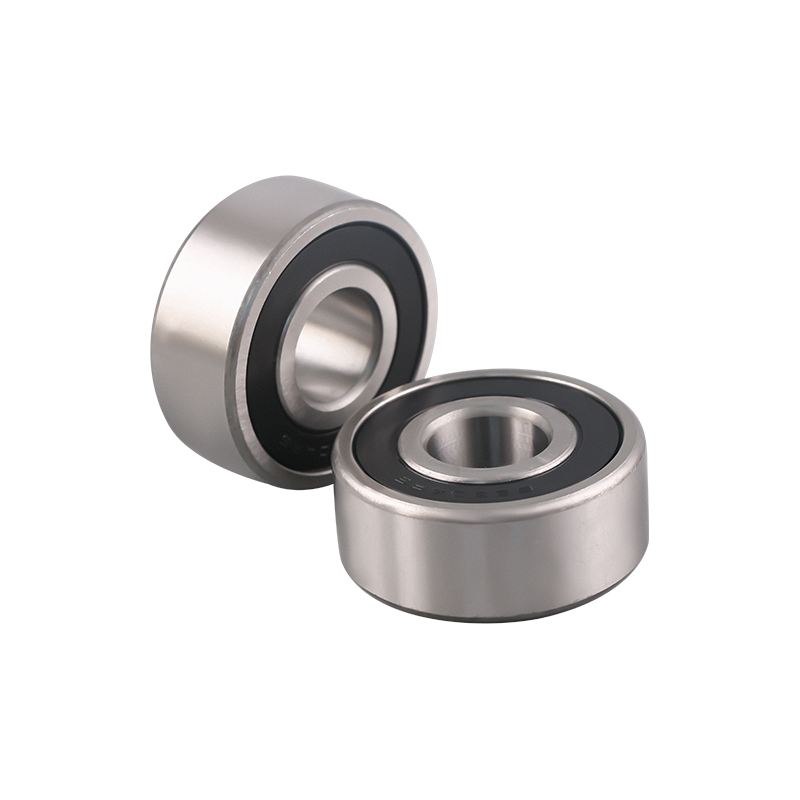

62303 ZZ/2RS Open 17x47x19mm Thickened Chrome Steel Bearing Deep Groove Ball Bearing

Deep groove ball bearings (DGBBs) are the most common type and serve a wide variety of industries.

Besides radial loads, the bearings can take axial loads in both directions and offer low frictional torque and high-speed components ideal for applications requiring low noise and vibration.